A reliable and trusted leader in innovative, certified building solutions, establishing global standards of excellence and reliability in every project delivered.

Who We Are?

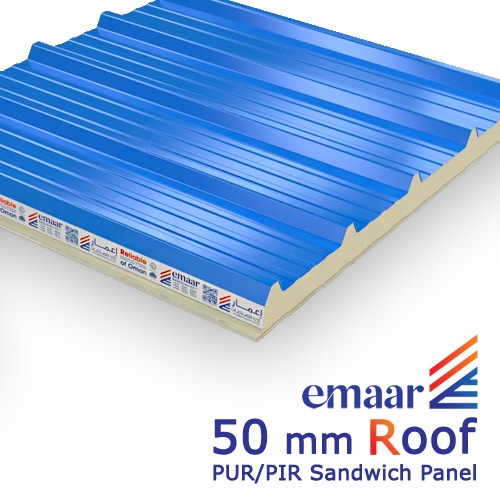

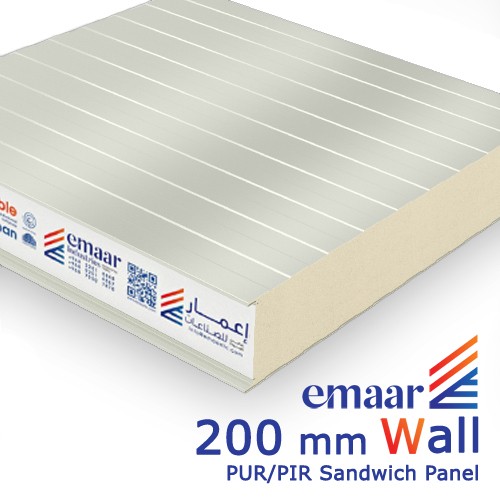

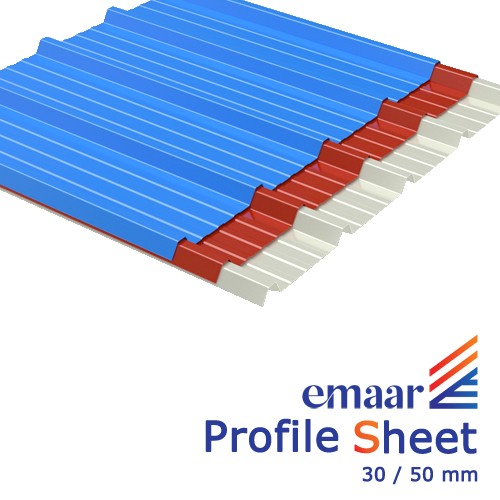

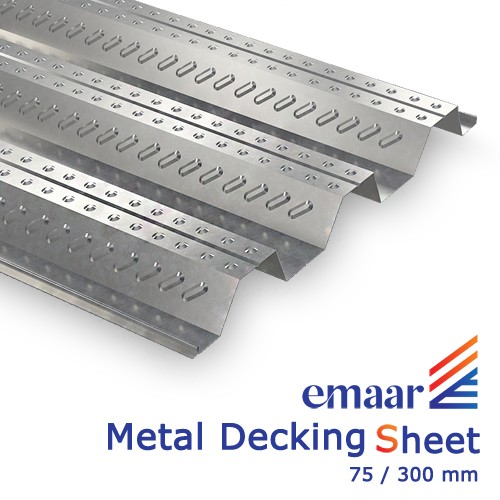

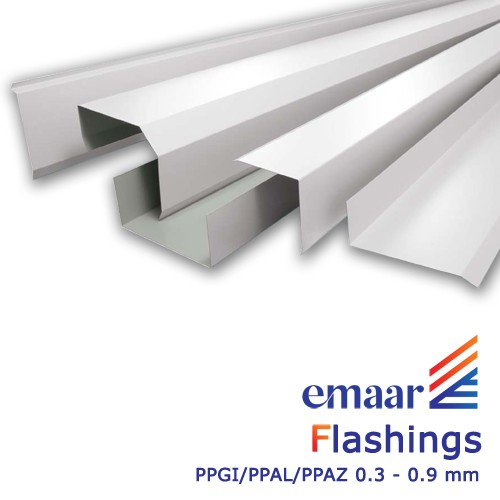

Emaar Industries, established in 2018 near Muscat, Oman, is a leading manufacturer of high-quality sandwich panels and innovative building solutions. Our state-of-the-art 22,000 sq.m facility, equipped with five advanced production lines, enables us to offer over 135 product variations, including energy-efficient and durable solutions that meet global standards. With a team of over 200 skilled professionals, we specialize in providing reliable, sustainable products for the industrial and construction sectors, ensuring superior performance, safety, and innovation in every project.

We’re proud to have collaborated with these esteemed organizations on innovative construction projects, delivering high-performance sandwich panels that stand the test of time.