Emaar

Forming Products

Emaar Forming Products is a leading manufacturer of metal forming products for the construction industry. Their products are used in a variety of applications, including sandwich panel installation.

Here are 5 essential Emaar forming products for sandwich panel installation:

Emaar Corrugated sheets Description

Emaar Corrugated sheets Description

Corrugated sheets are thin, flat panels made of a durable material, typically metal, that feature a series of parallel ridges and grooves. These ridges and grooves give the sheet a wavy or corrugated appearance. Corrugated sheets are commonly used in construction, roofing, and cladding applications.

The term “sandwich panel” refers to a composite building material that consists of two outer layers (skins) and a core material sandwiched between them. The outer layers can be made of various materials, including metal, fiberglass, or plastic, while the core material is typically an insulating material such as foam or rock wool.

When we combine the concepts of corrugated sheets and sandwich panels, we get corrugated sandwich panels. These panels utilize corrugated sheets as the outer layers and have a core material sandwiched between them. The corrugated sheets provide structural strength and rigidity to the panel, while the core material provides insulation and additional strength.

Corrugated sandwich panels are widely used in the construction industry for roofing, wall cladding, and industrial applications. They offer several advantages, including lightweight construction, high strength-to-weight ratio, thermal insulation, sound insulation, and resistance to weather elements.

These panels are relatively easy to install and provide a cost-effective solution for building exteriors. They are available in various sizes, colors, and profiles, allowing for versatility in design and architectural applications.

Overall, corrugated sandwich panels combine the benefits of corrugated sheets, such as strength and rigidity, with the advantages of sandwich panels, such as insulation and versatility. They are a popular choice in construction for their durability, functionality, and aesthetic appeal.

EMAAR FLASHING Description

EMAAR FLASHING Description

A flashing for sandwich panels is an essential element in the proper installation of sandwich panels. This term refers to a sealing or connection system between the sandwich panels and the structure. Flashings are typically made of metal (such as aluminum) or polymer (such as PVC) and are installed on the edges of the sandwich panels. The main purpose of sandwich panel flashings is to create compression and tightness between the panel edges, preventing the entry of air, water, dust, and insects into the structure. Flashings act as a crucial element in the insulation and sealing system of sandwich panels, enhancing the effectiveness and performance of the structure and aiding in energy conservation and temperature control inside the building.

Flashings can be prefabricated and installed on the panels or installed separately. The design and size of flashings vary depending on the type and dimensions of the panels and the requirements of the structure.

EMAAR PURLINS Description

EMAAR PURLINS Description

Purlins in a sandwich panel system are elements used to create the primary structure of the roof or the support system for the sandwich panels. Purlins are typically positioned horizontally and serve as key components in the placement and support of sandwich panels.

The main functions of purlins in a sandwich panel system involve two important roles. Firstly, they act as the main structural framework for the roof, transferring the loads generated by the weight of the sandwich panels and other loads to the main structure of the building, such as columns and walls. Secondly, purlins serve as the primary connections for installing the sandwich panels. The sandwich panels are usually fastened to the purlins using screws or other types of connections to secure them in place during installation.

The structural materials used for purlins can include light steel, stainless steel, wood, or composite materials. The size, shape, and type of purlins depend on the structural requirements and the sandwich panel system design, and are determined based on the specific design and specifications of the structure.

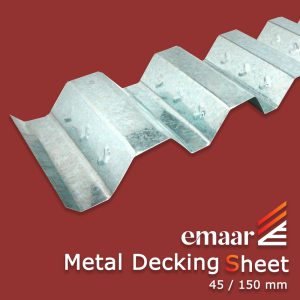

EMAAR DECKING SHEET Description

EMAAR DECKING SHEET Description

In a sandwich panel, the term “decking sheet” refers to a sheet that is used as the top layer of the sandwich panel. This sheet is typically a metal sheet (such as steel or aluminum) that is placed as the outer layer of the sandwich panel.

The primary function of the decking sheet in a sandwich panel is to protect the core of the panel and provide resistance against mechanical loads and external damages. In addition to providing a protective cover, the decking sheet can enhance the stiffness and strength of the structure and protect the panel against impacts, corrosion, water and moisture penetration, and other environmental factors.

The sheets used in decking sheets are often available with various coatings such as paint, galvanized coating, aluminum coating, etc. The choice of materials and the thickness of the decking sheet depend on the structural requirements and the intended environmental conditions and should be selected in accordance with relevant standards and construction practices.

EMAAR CURVE SHEET Description

EMAAR CURVE SHEET Description

The Ridge Curve Sheet sandwich panel is similar to other sandwich panels, but with the distinction that its top and bottom edges are uniquely curved. This type of panel is typically used to create curved roofs or specific sections of a building that require specialized design. The curved design of these panels enhances the aesthetics and adds extra strength to the structural components of the building.